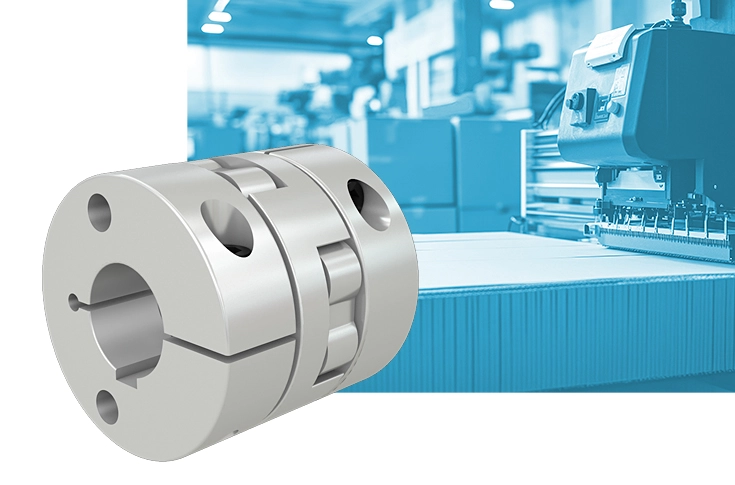

Compact precision coupling for complex production processes in assembly lines

04.02.2026

Efficient and scalable – that's how automatic and semi-automatic assembly lines present themselves. They guarantee that even complex manufacturing processes can be designed to be highly productive. Shortened assembly times through optimised cycle and clock rates with fully synchronised workflows are a top priority. These lines are modular and tailor-made for a wide variety of work steps and are adapted to individual assembly requirements as much as possible. Synergy and perfect interaction between humans and machines, i.e. collaborative robotics, often play a major role. In most cases, the systems are designed to make optimum use of space.

In such assembly lines with compact installation conditions, the torsionally-stiff Semiflex precision coupling supports the synchronised process flow to the individual processing stations. The all-metal coupling combines high torsional rigidity and torque capacity with high displacement capacity in the slimmest design. The C 70 size used is designed for flange mounting and, with an overall length of only 35 mm, offers the shortest possible design. Despite these compact dimensions, it offers a radial displacement capacity of up to 5 mm.

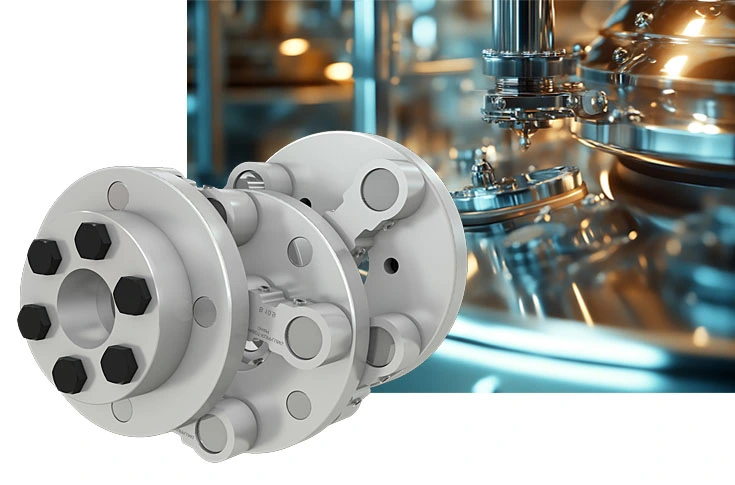

Servo disc coupling as an integral component in high-acceleration separation systems

07.01.2026

As a child, you loved it – the chain carousel. You took your seat in the gently rocking passenger seats attached to chains, full of excitement and anticipation. Then a signal sounded and off we went. The faster the rotation became, the more we felt like little pilots, as we were pulled more and more to the side as if by magic and literally floated through the air. Today, as adults, we know that it wasn't magic, it was centrifugal force that gave us these unforgettable experiences. And what leaves a lasting impression on us does not stop at technology. State-of-the-art separators use precisely this centrifugal force to separate solids from process fluids or to separate different phases of varying densities from each other, for example. The Servoflex servo disc coupling proves to be a perfectly matched partner in the drive unit of a vertically arranged separator. With minimal inertia and high precision, the lightweight and torsion-resistant compensating coupling does its job. It easily copes with even the highest acceleration in the vertically arranged separation plant, supporting fast and efficient isolation of the materials.

Servo disc coupling: High dynamics and positioning accuracy in the assembly process

03.11.2025

Printed circuit boards as carriers of electronic components are now part of almost every electronic device. The electronic components are usually applied to the PCB using a soldering process. However, due to increasing large-scale production - for example in the automotive sector due to increasing demand for built-in electronics for communication purposes - press-fit technology has increasingly established itself in some industries instead of soldering technology. Components are attached using connecting pins that are pressed at high speed into the metal holes provided on the PCB. This PressFit connection creates a conductive contact. The press-fit process is carried out without thermal stress on the PCB, and subsequent sustainable recycling is easily possible by simply pressing it out. The realisation of an extremely high output rate is the focus of such a fully automated system. The pins are precisely positioned and pressed into the contact holes provided for this purpose in extremely fast placement processes. The contact pins are located on a rolled-up belt and are transported precisely to their position for further processing by means of two placement heads working in parallel. A combination of servo motor and recirculating ball screw with the backlash-free Servoflex servo disc coupling is used in the XY axis to ensure the necessary high-precision positioning for the placement process. The double-cardanic precision coupling combines pronounced torsional rigidity for the high-precision work process with the required universal displacement capacity. The low mass moment of inertia anchored in the Servoflex genes promotes the high output of the system, which operates dynamically in a permanent acceleration and stopping process. It runs in 24/7 operation. It only stops when the belt is changed or when a flexible changeover to a new placement process with alternative pin sizes and formats is carried out. The servo disc coupling is optionally available for production processes in the semiconductor industry under clean room conditions as a clean room-compatible version adapted for this purpose.

Compact coupling for customisable mixing and kneading processes

01.10.2025

Compact coupling for customisable mixing and kneading processes

Lunch break - time for a little time out, without a computer, with a small snack. Would you prefer something sweet with a soft bite or a rustic wholemeal or rye flavour? The spontaneous choice falls in favour of the latter. So we reach into the handy, colourfully printed paper packaging. Carefully layered, the thin, crispy slices of crispbread await us. Combined with fresh spring quark - thanks to the serving suggestion shown on the outer packaging - this is now applied to the surface, which is sprinkled with tasty sesame seeds. Finally garnished with some finely chopped chives, the small, tasty treat is ready and the envious looks of our colleagues are guaranteed. But before we can bite into the crispy crispbread to the sound of its typical crunch, this cereal product goes through a multi-stage production process. One of these is the actual mixing and kneading process, in which the dough is brought to its homogeneous, ready-to-bake consistency. Individually adjustable mixing tools and height-adjustable discharge components for customisable dosing quantities guarantee an even and optimally coordinated throughput in such a system. The Schmidt-Kupplung coupling supports the continuous mixing and conveying process with its variable adjustment options and permanent synchronisation. In accordance with the strict hygiene requirements for food processing machines, the compact coupling has a smooth, easy-to-clean, corrosion-resistant nickel coating. The uniform and non-porous layer thickness created by chemical nickel plating offers excellent corrosion and wear resistance. The coupling is also available in a stainless steel version as an option. .

Servo disc coupling: High positioning and repeat accuracy in the cutting processs

01.09.2025

Waterjet cutting technology is a versatile process for separating and cutting fine contours and shapes. Almost any material can be processed precisely. In addition to metals, this can also include glass, granite, ceramics, composite materials or plastics. As this technology processes the materials with virtually no heat input, there is no deformation in the cutting area, which has a positive effect on the quality of the cut edges achieved. In the waterjet cutting process, water is compressed under extreme pressure. Depending on the requirements and workpiece, this is then pressed through special nozzles with customised diameters. This achieves the required exit speed with the narrowest kerf for a precise cutting process. A combination of servo motor and ball screw with the Servoflex type SFC 050D works in the axes of a waterjet cutting machine set up as a gantry system to provide the necessary high-precision positioning and repeat accuracy for the cutting process. Designed as a double-cardanic version, the coupling size with an external diameter of 56 mm offers a torsional rigidity of 16,000 Nm/rad and therefore has maximum torsional rigidity and precision. In order to also realise the high cutting performance and speed, the system works dynamically in a permanent reversing acceleration and stopping process. The Servoflex impresses here with its extremely low mass moment of inertia. Due to the selected bore diameters, the backlash-free clutch is also equipped with a stepped clamping hub with reduced mass inertia on one side. The size has a nominal torque transmission capacity of 25 Nm and compensates for radial misalignments of up to 0.28 mm and axial misalignments of up to 0.8 mm. It is available for speeds of up to 10,000 rpm.

Even more versatile thanks to even more options

The Servoflex servo disc coupling is versatile and precisely adapted. In addition to the version for smooth shafts, various options are available - for example with keyway for additional positive locking, with customised overall length thanks to variable-length spacers or as a cleanroom version.

Precision couplings for intralogistics

01.08.2025

Efficient material flow with its sub-areas of conveying and palletising technology is an important component in today's logistics for optimising internal material processes. Whether unit loads are conveyed from A to B on rollers or belts with pinpoint accuracy, whether small parts are stored and picked at breakneck speed, or whether palletising robots assemble and load packaged end products onto conveyor systems with high precision - for all these tasks, the coupling is of great importance for a precise and smooth process.

Find out more about our compact precision couplings for demanding applications - from storage and retrieval machines and parcel robots to modular belt conveyors for the food industry and highly efficient storage systems - in our ‘Material flow’ industry section.

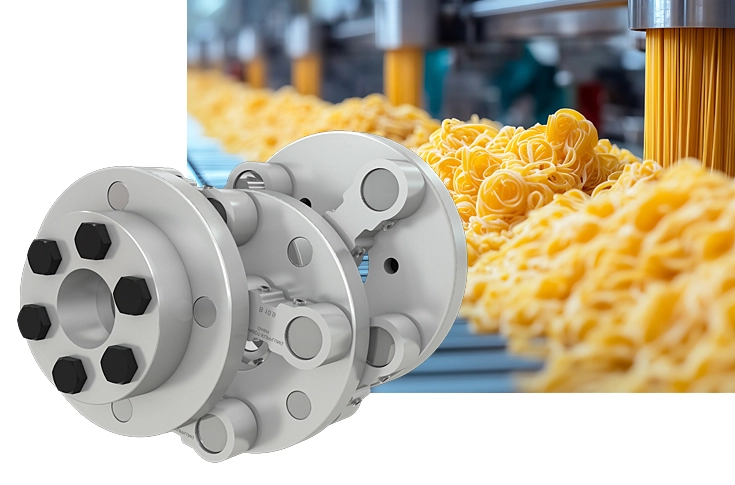

Precision couplings in the drive of compact modular belt conveyor systems in the food industry

01.07.2025

Trigoni with an exquisitely nutty truffle filling, tortellini carefully and skilfully wrapped in a spicy, Mediterranean-flavoured tomato and mozzarella mixture - who doesn't get their mouth watering at the sight of this? From children to adults - almost everyone loves this delicious pasta, which is not only tasty, but also gives you a hint of Italian flair with a corresponding holiday atmosphere. But before these southern delicacies finally end up in our fridge and then on our plate, they go through various production and packaging processes. These range from portioning and dosing processes to automated product handling. In the latter step, the food products are distributed, grouped and then packaged ready for dispatch. For these sub-processes, fully automatic and easy-to-clean modular belt conveyors are used in the food industry to transport the packaged or unpackaged food products with pinpoint accuracy.

Modular in design, they transport the products through curves and inclines without slippage. In the drive of such modular conveyors, the pasta products are first lifted in the first sub-segment in continuous cycle operation, depending on the type of processing, and then transported onwards to the individual stations with high precision. Depending on the height of this initial radial lifting movement, precision couplings from the Semiflex and Schmidt-Kupplung series take over the precisely defined lifting process during operation in an extremely space-saving manner. In accordance with the hygiene regulations in these systems, the couplings are made of stainless steel and equipped with high-quality food-grade lubricant. For installation spaces that are difficult to access in these compactly designed and laid out conveyor systems, the shaft couplings are available not only in versions for flange-mounting to customer-specific components, clamping hub and form-fit hub versions, but also as radially mountable clamping hub versions or with clamping hubs in split design.

Extremely space-saving precision coupling for the production of safety vehicle restraint systems

10.06.2025

Road traffic density has increased continuously over the past few decades. There are many reasons for this. In the logistics sector, for example, the vast majority of goods are transported by lorry. Statistics also show that over 60% of commuters use their cars to get to or from work. For summer holidays, according to surveys, the majority of travellers also prefer this vehicle as a means of transport to their long-awaited holiday destination. As a result, we spend the majority of our business and private journeys on the road.

Overtaking manoeuvres, signs with speed limits or the friendly-sounding, directional voice from the navigation system - while driving, we always focus on what is happening on the road. However, there is one thing we hardly notice, even though they line the road for kilometres like a guardian angel - safe vehicle restraint systems. These profiled and therefore extremely powerful crash barriers offer a high level of safety potential for vehicle occupants in the event of a collision thanks to their high degree of efficiency.

But how are these protective devices, which offer such sophisticated protection despite their low weight, created?

Gain profile with precision and compactness!

Profiling systems are the solution to this problem. These moulding systems produce the corresponding continuous box and grid profiles in a multi-stage forming process. Thanks to its high radial displacement capacity, the slimline Semiflex precision coupling is the ideal partner for the various functional adjustment movements in the forming machining process.

Thanks to its compactness, it enables the various roll forming stations to be connected in the tightest of spaces. Depending on the requirement profile, the all-metal coupling, equipped with split clamping hubs, enables radial assembly and disassembly without axial displacement of components or is available for very restrictive installation conditions, for example with internal clamping sets.

Find out more about our compact precision couplings for demanding rolling, stamping, pressing or forging tasks - from punching machines to roll bending machines and stretching rollers - in our industry section "Forming technology".

Compact precision couplings for dynamic and precise handling and manipulation tasks

02.04.2025

Handling technology encompasses comprehensive process steps that serve to optimise a wide range of production processes. These include handling and assembly technology, automation and the entire field of automation and robotics. Due to the highest demands in terms of productivity and output, the systems operate highly dynamically in continuous or intermittent cycle operation using state-of-the-art servo technology. SCHMIDT-KUPPLUNG offers a wide range of different shaft couplings for this purpose - precise, with high torsional or axial rigidity and a lightweight design.

Perfect synchronisation of work processes in the fully automated assembly system

Joining, screwing, pressing, assembling or labelling - it's easy for modular, system-integrated rotary indexing machines that use indexing tables to handle these different operations with high productivity The workpieces to be processed are placed on the rotary indexing table using a fixture This pick-up then cycles from work station to work station accordingly In order to ensure that the workpieces are processed in large quantities, a precise and time-efficient process is essential This means that precise and highly dynamic drives are required for perfect synchronisation and control to the respective, usually pneumatically operated handling stations.

With its torsionally rigid and high-torque character, the compact Semiflex Dynamic shaft coupling is a perfectly coordinated integral component in the drive train Thanks to its slim and lightweight aluminium design, it supports the precise, highly dynamic work process.

Linear coupling for precise feed tasks in the highly productive gantry portal

Whether for high-precision contour machining in series part production or for palletising tasks in conveyor and storage technology or for the controlled joining process of metallic materials - electrically or pneumatically driven linear axes form the basis for dynamically operating handling and handling systems in these fully automated work processes.

They are usually modularly designed as multi-axis gantry portals in order to fulfil these tasks in a highly productive manner.

Such feed tasks are the speciality of the axially rigid linear coupling Loewe GK Linear. For example, the size Loewe GKL 27 cardan coupling has proven to be the ideal partner in dynamic traversing units in the drive train consisting of a linear motor and traversing carriage. In line with the high positioning accuracy and acceleration rates of the axes, the linear coupling made of aluminium has a high axial rigidity of 16,000 N/mm and extremely low mass inertia. It is available for maximum axial loads of up to 800 N and, as a compensating coupling, is also able to compensate for radial misalignments of up to 1 mm and angular misalignments of up to 3°.

Find out more about our compact precision couplings for demanding handling tasks - from automatic assembly machines and gantry systems to cobots and servo presses with extremely high thrust forces - in our "Handling technology" industry section.

Compact precision coupling for the high demands of fully automated thermoprocessing systems in the food industry

03.03.2025

Refining delicacies such as sausages or fish products to perfection - unthinkable without thermoprocessing systems. They ensure that we can find and enjoy the deliciously presented, smoked salmon at festive events or when visiting the hotel buffet in the morning, for example. Thanks to a considerable degree of automation, modern food production systems fulfil the high demands on the desired output in combination with optimum quality in terms of the sensory experience in terms of appearance and taste. The systems also offer flexible adaptation to the processing of different products.

The products to be processed pass through a wide variety of treatment processes in one system. The production stages are divided into heat treatment and cooling processes. This means that several thermally different processes such as drying, smoking, cooking, scalding, showering and cooling come together in the overall process.

The drive in such a fully automated system takes place outside the actual product area in a continuously operating process.

Due to the thermally different treatment stages, any tensions and displacements in the drive train must be absorbed by the shaft coupling to be used. Furthermore, quick and easy installation with the smallest possible dimensions is required.

Tasks made for the Semiflex Compact Plus precision coupling. In addition to compensating for axial and angular misalignments, it offers a high radial misalignment capacity combined with a compact design. Equipped with clamping hubs, the coupling offers the desired convenient and quick assembly and disassembly by fastening and loosening a radially operated screw.

For systems in the food industry with frequent cleaning processes or in accordance with the strict hygiene requirements for food processing machines, the compact coupling is available with a smooth, easy-to-clean, corrosion-resistant nickel coating or as a stainless steel version.

Find out more about our compact precision couplings for demanding packaging tasks in our "Packaging machines" industry section - from tubular and flat bag machines to fold wrapping and hygienic filling machines.

Precision coupling for compact, fully integrated beverage packaging system

03.02.2025

Innovative, fully automatic packaging machines for beverages integrate the various process steps from feeding, filling and sealing the bottles or cans with the tasty and thirst-quenching refreshments through to labelling and palletising in sleeves, baskets or fully sealed packaging in a fully integrated overall system. Thanks to this dynamic technology, these systems achieve a high output with a small footprint.

In such packaging machines with extremely compact installation conditions, the torsionally rigid Semiflex precision coupling supports the synchronised sequence process to the individual processing stations. In the Compact Plus version, the all-metal coupling combines high torsional rigidity and torque capacity with a high displacement capacity in the slimmest design. In accordance with the strict hygiene requirements for food processing machines, the compact coupling has a smooth, easy-to-clean, corrosion-resistant nickel coating. The uniform and non-porous layer thickness created by chemical nickel plating offers excellent corrosion and wear resistance.

Find out more about our compact precision couplings for demanding packaging tasks in our "Packaging machines" industry section - from tubular and flat bag machines to fold wrapping and hygienic filling machines.

06.01.2025

"It must be coming slowly"...another check of the clock, the delivery company's app announced that the doorbell was about to ring. And then the doorbell rings. Hastily and eagerly we jump up and rush to the door - there he is, the delivery man dressed in the characteristic colours with the long-awaited parcel. We happily receive it and open the parcel, usually without a second thought, the outer packaging that protects our precious contents. We often forget that this parcel, made of corrugated cardboard, is the decisive factor in ensuring that we hold our ordered goods in our hands in pristine condition. But how is this protective and inherently stable outer packaging actually made?

The manufacturing process usually takes place on inline machines consisting of several sub-units. These produce the finished corrugated board packaging from sheets of cardboard. The sheet passes through the feeder, printing, creasing and slitting unit as well as the punching and folding station before being glued together in the folder gluer to form the finished package. In such packaging machines with extremely compact installation conditions, the torsionally rigid Semiflex precision coupling supports the synchronised sequence process to the individual processing stations. In the Compact Plus version, the all-metal coupling combines high torsional rigidity and torque capacity with a high displacement capacity in the slimmest design. The flange-mounted version ensures integration in the tightest of spaces in customised attachments (example size C 265, outer diameter 100 mm, overall length 88 mm, nominal torque 265 Nm, radial misalignment capacity of up to 8 mm).

Find out more about our compact precision couplings for demanding packaging tasks in our "Packaging machines" industry section - from tubular and flat bag machines to fold wrapping and hygienic filling machines.