In forming technology processes, mostly formed materials are subjected to various specific changes in shape. Since these forming processes are often carried out through rolling, pressing or forging operations with high impact torques, couplings must be high-torque, precise, torsionally stiff and sturdy, as well as having high displacement and offset capacity.

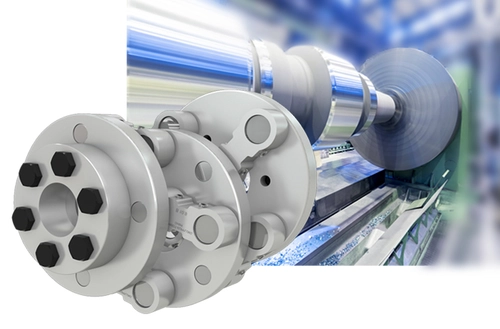

Roll feeds

Cycle-operated, precise feeding of metal sheets

At the start of a system, so-called roll feeds are often used to convey metal sheets to the actual forming process. They push and pull materials with great precision, automatically and in fixed-cycle operation to the subsequent forming press or roller. Couplings from the Schmidt-Kupplung series are used in such feeds. The torsionally stiff couplings are primarily equipped with friction-locking clamping hubs, keeping the torque peaks occurring during fixed-cycle operation into account.

In special systems with overly tight installation conditions, couplings from the Schmidt-Kupplung Power Plus series were selected for maximum torque transmission in a compact design.

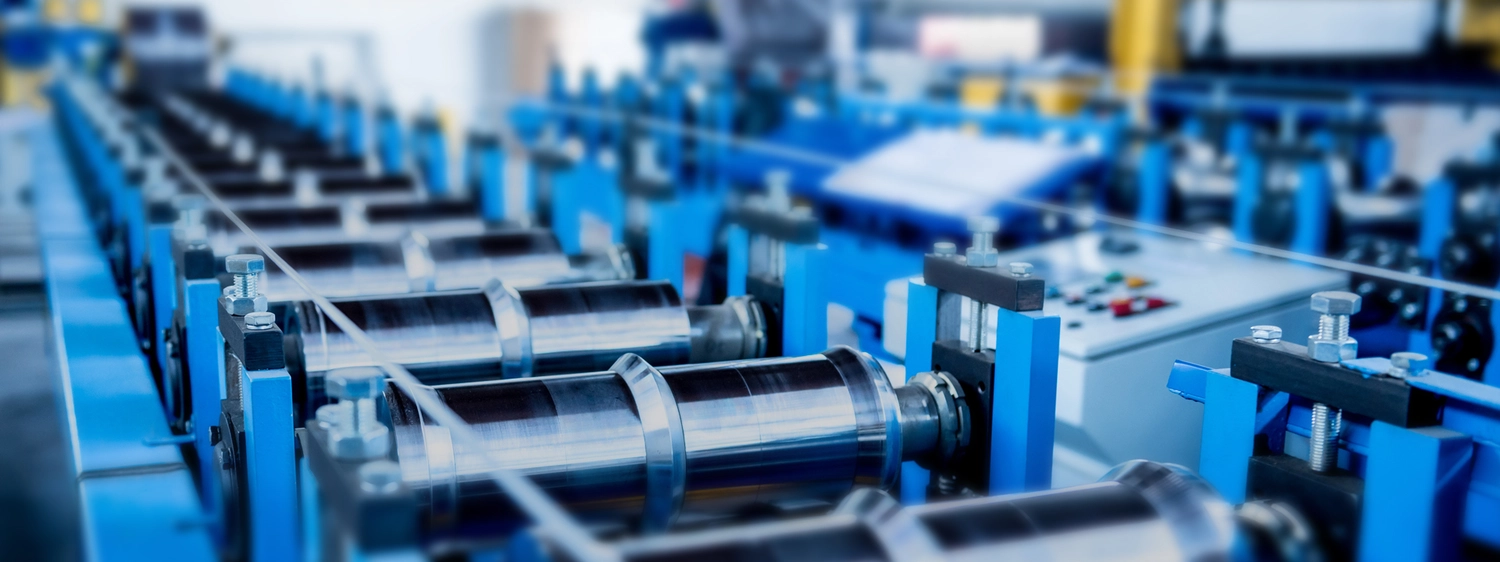

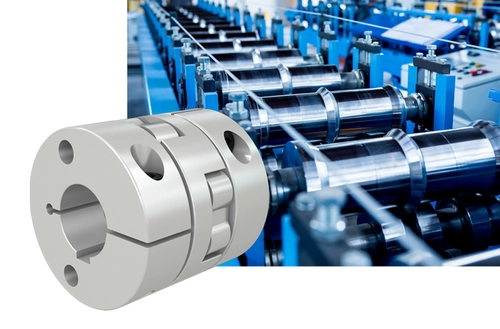

Profiling systems

Synchronising single profiling stations in a confined space

Profiling systems produce roll-formed profiles in a multi-stage forming process. The range of possible shapes is quite varied. As a result of its high radial displacement capacity, Semiflex is the right choice for the various adjustment movements occurring during the machining process.

Due to their compactness, these couplings enable countless profiling stations to be connected in the smallest of spaces. Clamping hubs make radial assembly and disassembly possible without any axial displacement of components. Semiflex clamping hubs are used in various types of profiling systems. Here, too, there are only extremely restrictive installation conditions. A special version of the Semiflex Compact Plus coupling with internal clamping sets can solve this issue.

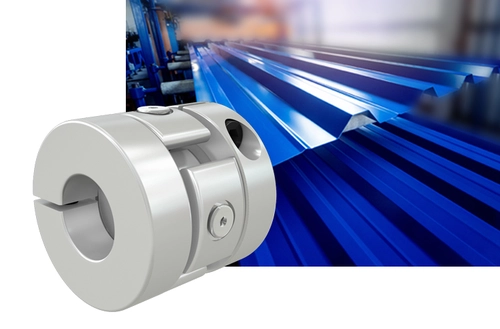

Embossing and punching machines

High performance in embossing, punching or finishing processes

The compact and precise couplings of the Schmidt-Kupplung and Semiflex series are used in meticulous, synchronised work processes such as metal sheet conveying in case of trimming and punching products as well as in embossing rollers.

These couplings are also used in the drives of trimming shears, used in the final step of metal sheet processing.

Axially stiff Loewe GK couplings are specifically intended for metal sheet processing if axial forces occur in the application in addition to the torque.

Pipe bending machines, forging rollers

Sturdiness and permanent adjustment when processing metal tubes

Pipe bending is the process in which round, square or profile tubes are formed using several calenders. Semiflex and Schmidt-Kupplung couplings are distinguished by ease of offset and high torque.

Semiflex and Schmidt-Kupplung couplings are used in special machines for processing metal pipes where demands on radial displacement and adjustment movement are particularly high. In the machining process, pipes are cut to length, grooved on the outside and then checked and sorted in a final process.

High universal offset paired with robustness

The hardest impact moments per work cycle occur when chassis parts are manufactured. The material is pre-formed, bent and perforated using forging rolls through multiple work steps in fixed-cycle operation. As a result of adjustment movements due to different shaping and thickness variations during material processing, high parallel and angular displacements occur and are implemented by the Omniflex series couplings.