Couplings in applications under vacuum conditions have to meet special requirements. Materials need to be carefully selected according to the vacuum level. For example, outgassing materials should be avoided. Using stainless steel for coupling parts is also frequently required.

SCHMIDT-KUPPLUNG supplies coupling systems tailored to these operating conditions.

Wafer fabrication, control and measurement

Accurate transportation in wafer fabrication

Wafers play a fundamental role in photovoltaics. Solar cells for solar modules are made out of them in several production steps. The manufacturing process is very complex, with wafers needing to be meticulously conveyed to each of the process chambers after initial ejection.

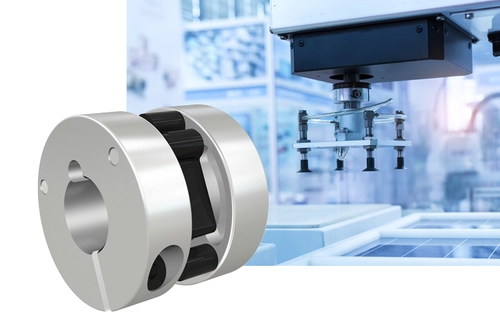

Couplings from the Controlflex range are used to precisely convey wafers after they have been sawn out of so-called silicon ingots.

Monitoring of the workflow in vacuum systems

In most vacuum technology processes, precise workflows are monitored by sensors and rotary encoders. These are usually rotary encoders specially customised for vacuum technology, which, e.g., monitor the coating process of silicon wafers in semiconductor production. Encoder coupling Sensorfit with PPS hubs and a POM functional element ensures a vacuum-compatible minimum outgassing behaviour as well as precise recording and transmission of measuring pulses.

Precision in the thin-film process

Uniform coating of the finest functional layers

Due to the special pressure conditions arising in the vacuum, a wide variety of materials can be provided with wafer-thin – mostly metallic – layers in the thin-film process. This includes, among other things, the vacuum coating of special glasses, displays, flat screens, photovoltaics and special films.

Coated foils are of great importance - for example in the food industry - as capacitor, solar or transformer foils. So-called roll-to-roll systems are used to produce them.

The couplings of the Semiflex range, made of appropriate steel and specially customised for vacuum technology, operate in these systems.

An important feature of the Semiflex couplings which are used in these systems is that, despite displacement compensation, permanent sync is guaranteed, which is essential to evenly apply micro- to nano-thin functional layers.

Vacuum curing systems

Defying heat when adjusting flaps

SCHMIDT-KUPPLUNG supplies special versions of the Loewe GK coupling range for vacuum curing systems. They are used in flap adjustments being controlled through pivoting movements. The axially fixed couplings provide high combined radial and angular displacement capacity. All components are made of stainless steel. Special thermally stable vacuum plain bearings work within axially stiff couplings suitable for thermal ambient conditions of up to 250°C.