26.11.2022

Modern drive concepts feature high dynamics, energy efficiency and increasingly compact dimensions, under the banner of high power density paired with outstanding energy efficiency. Requirements made for the Spinplus.

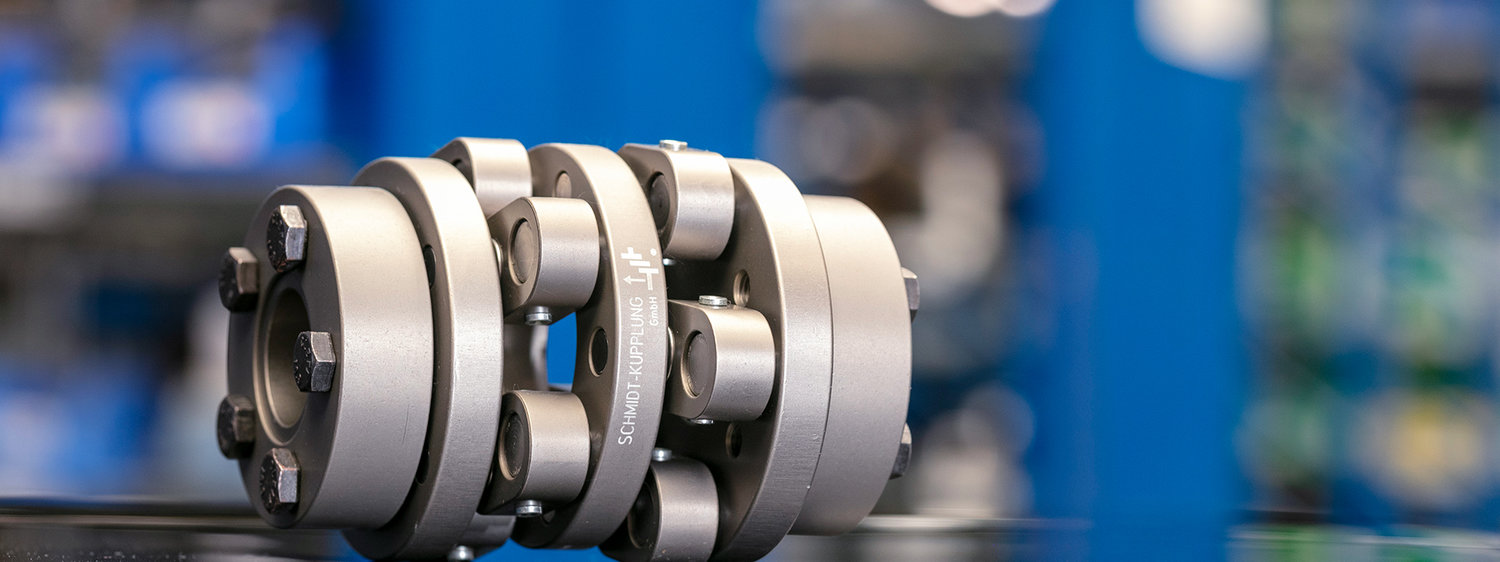

The Spinplus: a compact-sized coupling system with extremely low rotational inertia

The core of the Spinplus coupling is the functional element responsible for its operating and performance parameters. This new functional element is based on the principle of a parallel link system with flexure hinges and enables universal displacement compensation - i.e. compensation for radial, axial and angular shaft misalignments - in one plane. As a result of this ability, the backlash-free coupling is advantaged by an overly short design and high performance density, combined with extremely low rotational inertia.

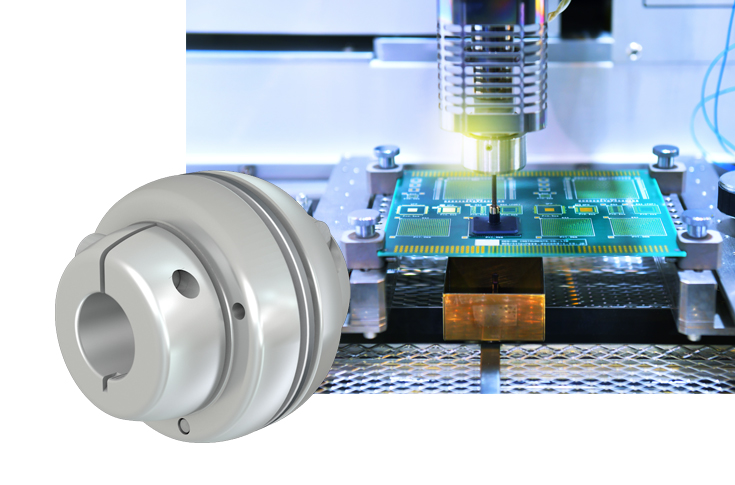

Innovative clamping hub design optimises the concept

In addition, the newly-developed, innovative hub design further optimises the concept of this torsionally stiff coupling in terms of reduced rotational inertia. These aluminium clamping hubs contribute to further reducing this parameter, as against conventional hubs. In this connection, two hub versions were designed to meet the respective application requirements. Equipped with offset clamping hubs, version A of the coupling is focused on providing the lowest possible rotational inertia. Version B is designed to accommodate large shaft diameters and features the shortest possible overall length. The clamping hubs are also anodised for corrosion protection.

Use in the dynamic, high-precision testing process for angle measuring systems

Testing devices for angle encoders enable rotary encoders such as resolvers, etc., to be referenced in high-precision measurements. On these test systems, for example, angle encoders from brushless EC direct current motors can be compared with the respective angle encoder of the test station. The measured values are made available on analogue and digital output channels so that they can then be precisely evaluated by a PC. This test process provides major results, since the motors, which work with high acceleration and in high speed ranges, are used in conjunction with the angle sensors for accurate positioning.

This is where Spinplus coupling size SP10-A with offset clamping hubs on both sides comes into play and exactly meets requirements in terms of high precision, according to the highly accurate measurement results to be achieved, the compensation of universal shaft misalignments, as well as the extremely low rotational inertia and operation in a wide speed range .