Machine tools are used to process workpieces and tools. Cutting machine tools include lathes as well as boring, milling and grinding machines. For all of the machine tools mentioned, what matters is speed, precision and exceptional cost-effectiveness. SCHMIDT-KUPPLUNG precision couplings are used in a wide variety of machine tools.

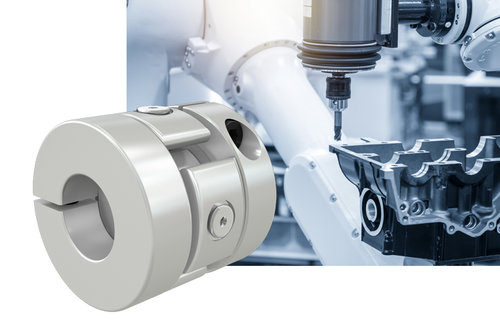

Bar feeder lathes

Axial stiffness for precise material feeding

Multi-spindle automatic lathes play an important role, especially in the production of large serial parts, due to their high productivity and exceptional cost-effectiveness. Axially stiff couplings Loewe GK are used for material feeding. High axial stiffness ensures precise bar feeding while providing outstanding compensation for any combined radial and angular displacement that occurs without deformation over a short overall length.

The machine’s feeding cables are seated in the inside of the articulated coupling, in a space specially designed for this application.

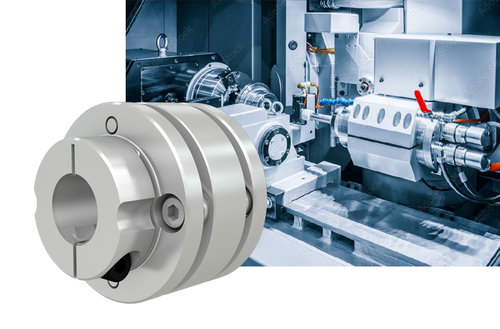

Lathe feed drive

Dynamic feed with the highest positioning accuracy

High demands are placed on the dynamic behaviour of feed drives in modern CNC lathes. On the one hand, exact positioning in feed movement is essential. This high positioning accuracy implies the high stiffness of the entire drive unit. This is made possible by the extremely high torsional stiffness and backlash-free operation of the Servoflex coupling.

On the other hand, feeding requires a high level of dynamics in order to fulfil the high level of productivity. As a result of their low rotational inertia and typical design, Servoflex couplings are the perfect solution. Ultra-high-stiffness versions of the Servoflex couplings are used in main spindles and feed screws where extreme stiffness of the system is required. Thanks to their extreme power density, Servoflex couplings guarantee small dimensions and thus low rotational inertia.

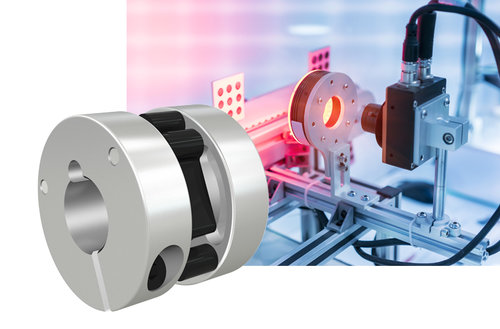

Control and measurement

Monitoring of the workflow in machine tools

In many tool technology processes, precise workflows are monitored by sensors and rotary encoders. The Controlflex encoder coupling ensures the exact and precise recording and transmission of measuring pulses. Leveraging its unique functional element, the compact rotary encoder coupling combines extremely low restoring forces and bearing-protection operation with an angle-synchronous transmission of the rotary movement. The coupling is electrically insulating, easy to assemble and designed for speeds up to 25.000 min-1.

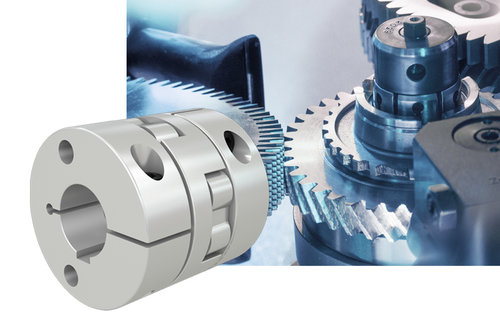

Gear cutting machines

High power density in gear cutting machines

Gear shapers are continuously running gear cutting machines for the production of straight or helical external or internal gears. In this respect, the so-called dividing wheels play a critical role. They synchronise cutting and work wheels for the machining process. In CNC gear shapers, the Semiflex series coupling, featuring a backlash-free clamping hub design, ensures precise drive for this dividing wheel. High radial displacement capacity is required from couplings in particular during workpiece machining, due to permanent feed motion.