Owing to to their precision, compactness as well as high radial displacement and offset capacity, SCHMIDT-KUPPLUNG couplings are used in a wide variety of packaging machines and processes.

They are employed, for example, in the drives of cartoning modules, folding boxes and folding units; in deep-drawing devices of thermoforming machines for the packaging industry; in filling systems or in label printing equipment marking products or packaged items with high output rates, or ensuring impeccable processes where loose products are grouped into saleable or transportable containers by means of fully automatic tray packers.

Tubular and flat bag machines

Highly dynamic processes in tubular and flat bag machines

Servoflex and Spinplus couplings are used in the servo-systems of the latest tubular and flat bag machines, which mostly work as universal forming, filling and sealing machines. Powdered or granulated products are poured into thermoplastic shells using a wide variety of dispensing devices, in line with the respective product requirements, and then heat-sealed. Highly dynamic, intermittent work processes, with reference to packaging material selection as well as automatic forming, filling and heat-sealing stations, are essential for the high output rates of these systems. By leveraging their design optimised in therms of rotational inertia, the backlash-free Spinplus and Servoflex couplings ensure the appropriate performance required by those systems.

Sealing/capping, folding and wrapping machines

Dynamics in the manufacture of reclosable beverage cartons

Beverage cartons often have so-called flat closures on the top. Liquids can be poured out without dripping. The carton can be easily reclosed and safely stored to protect it from foreign odours. The flat closures are applied to beverage cartons at extremely high output rates. In line with the dynamic process, lightweight aluminium Semiflex Dynamic couplings are used in closure application drives. Along with its compact design, it fulfils the low rotational inertia requirement.

Precise lifting and pivoting movement in the sealing process

The packaging of filled, ready-for-sale beverage cartons is often sealed by means of systems based on a combined linear and rotary movement.

To do so, the closures are positioned exactly on top of each packaging unit and then carefully screwed onto the locking thread with a defined torque. The main focus of this process is combining the precise linear movement required to exactly position the closure on the thread, with the rotary motion needed for an accurate movement sequence in terms of rotation angle and torque. Articulated coupling Loewe GK is specifically intended for this combined lifting and pivoting movement due to its high axial as well as torsional rigidity. Due to the properties mentioned, it promotes accurate sealing processes.

High output with fold wrapping machines

Compact, automatic fold wrapping machines are often used in the confectionery industry and pack small chocolate bars and similar articles with high output in corresponding wrapping materials. The Semiflex in clamping hub design is used in such compact machines. Due to its high torsional stiffness and precision, it supports the high productivity requirements when wrapping sweets inside and outside.

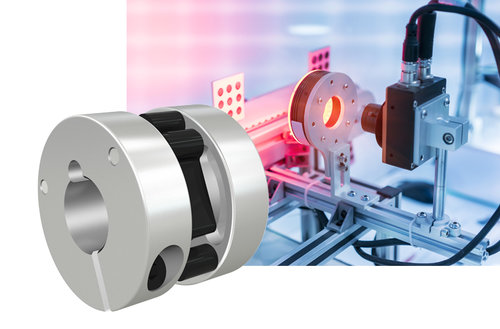

Control and measurement

Monitoring of the workflow in packaging machines

In most packaging industry processes, precise workflows are monitored by sensors and rotary encoders. The Controlflex encoder coupling with its balanced aluminium clamping hubs and unique functional element, as well as the Sensorfit coupling with its hubs made of FDA-compliant PPS material suitable for food-grade packaging machines, ensure exact and precise recording and transmission of measuring pulses.

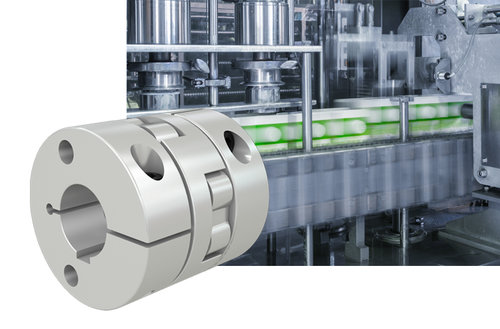

Filling machines

Precision and hygiene requirements in filling machines

For e.g. dairy products to reach the supermarket shelves ready for sale to the end consumer, they need to go through various production stages in combined cup filling and sealing systems. These systems run at an output rate of up to 50,000 cups per hour. The dispensing process is extremely important, as the contents of a cup must be kept constant with only minimal tolerances throughout the entire production process. For this purpose, the Loewe GK dispensing pistons of the Linear series, which are responsible for the filling quantity, are used for the precise linear drives. This articulated coupling is made of stainless steel and equipped with FDA-compliant plain bearings.

Tray packers

Tray packers are used to group and pack products dynamically and accurately

Frozen food, beverages, baked goods, confectionery, ready meals or other piece goods – all these products, whether loose or in bundles are grouped by fully automatic tray packers and packed in trays or covering boxes. Its modular structure, consisting of a handling and grouping unit, an erecting and filling module, and the final closing and lid placement unit, is carried out using modern servo technology. This is where the backlash-free and torsionally rigid Servoflex shows all of its strengths. It perfectly synchronises all processes. By leveraging its extremely low rotational inertia, it promotes the performance of these machines and the associated high output rates.